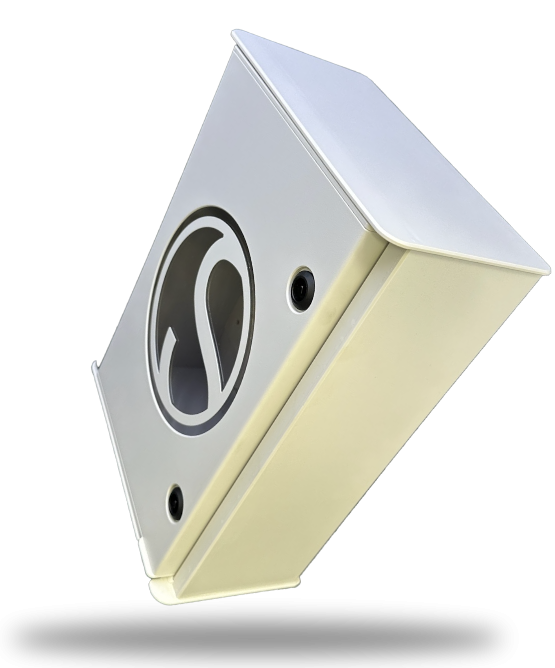

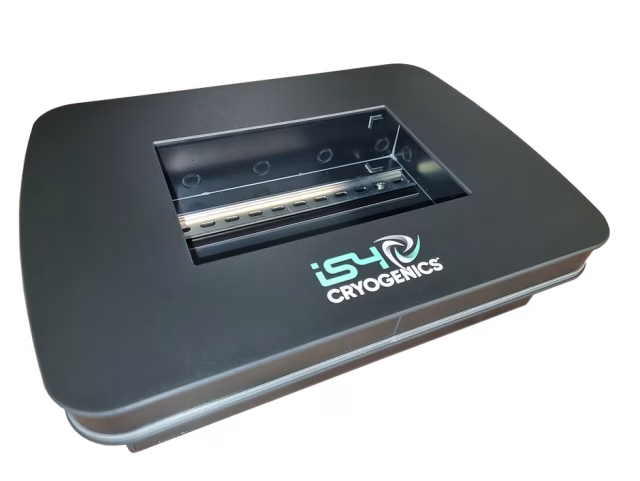

From concept to placement

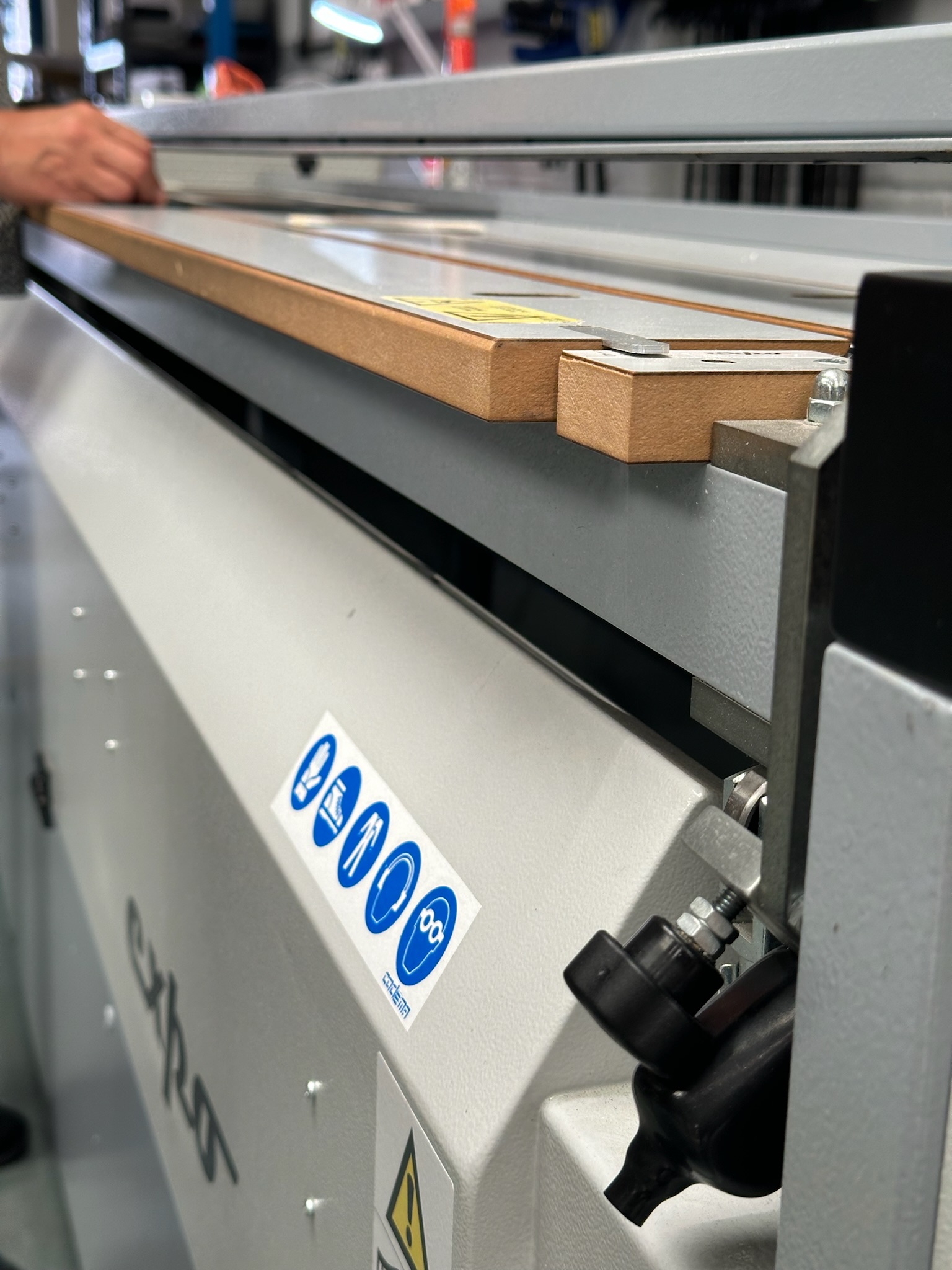

We understand the need for shortened supply routes and enhanced production control. Our manufacturing team learnt their trade developing and manufacturing medical and biotech devices. Bringing experience and a driven, consultative approach we are on hand every step of the way.