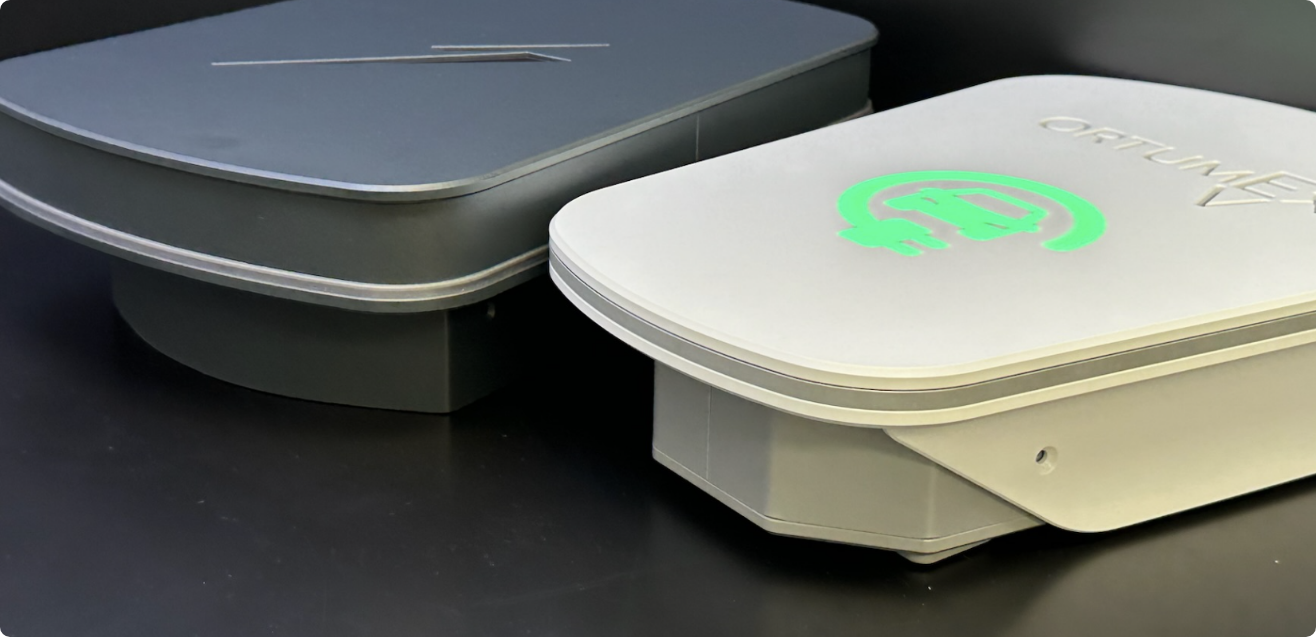

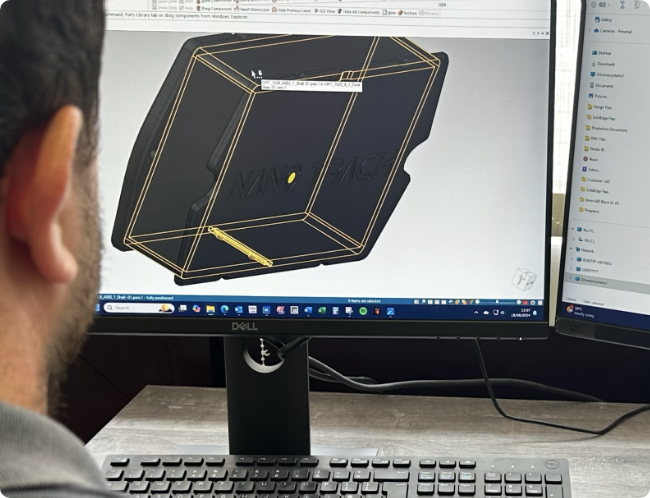

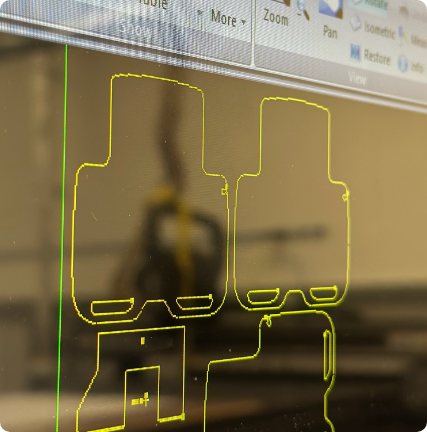

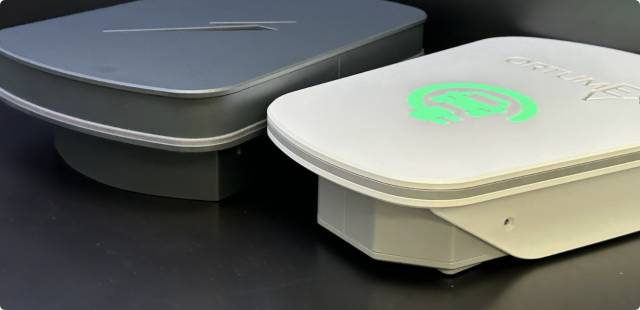

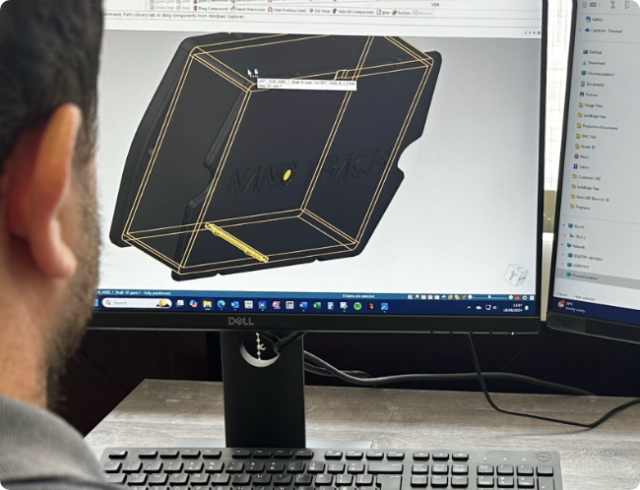

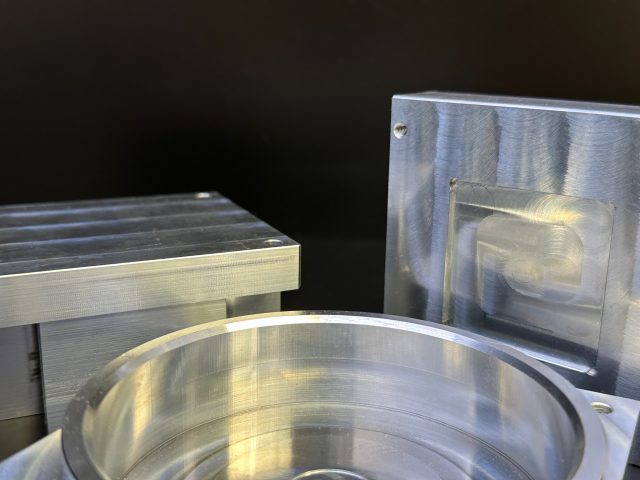

The Process

Based in the UK, our expert team is on hand to guide you through every stage of the process, from the concept, design and prototyping of your enclosure, through to fitting and aftercare. As your manufacturing partner, your experience with us is always our top priority.